ChemCad

CHEMCAD is designed to work for engineers and with engineers. Our proprietary solutions will allow your firm to work faster with more accurate results.

ChemCad

COSTELLO specializes in the sales and training in the use of ChemCad software. In addition, we are experts in building custom process models for our clients

SALES

COSTELLO provides ChemCad software as the authorized factory representative for the United States and Canada. In addition we provide training and custom simulation design for clients throughout the world.

TRAINING

COSTELLO provides custom training where your process model is built during the training session. We provide this service worldwide. These can be all types of simulations including biofuels, chemicals, specialty chemicals, pharmaceuticals, natural gas, incineration, and refining. Size of class can be 2 to 10 students at your location. Call for information.

PROCESS MODELING

Below is list of some of the process models we have prepared in ChemCad.

BIOFUELS

-

Ethanol (Sacharification, fermentation, distillation with molecular sieves or membranes)

-

Cellulosic Ethanol (Sacharification, C6 fermentation, C5 fermentation, distillation with molecular sieves or membranes)

-

Biodiesel (degumming, esterification and transesterification)

-

Biomass Gasification

-

Tire Pyrolysis

-

Wood Pyrolysis

-

Biogas purification

-

Fisher-Tropsch synthetic crude from biomass

-

Furfural from biomass

CHEMICALS

-

Nitric Acid

-

Sulfuric Acid

-

Hydrochloric Acid

-

Ethylene Oxide

-

Succinic Acid

-

Methanol to Gasoline (MTG)

-

Specialty Chemicals (21 different Models)

-

Pharmaceutical Intermediates (5 different Models)

NATURAL GAS

-

Amines (Various)

-

Selexol

-

Glycol Units

-

Liquid Sweetening

-

Turboexpansion Plants

-

JT Plants

-

Lean Oil Absorption Units

-

Demethanizers

-

Deethanizers

-

Depropanizers

-

Multistage compression

-

Purple Sandwich

-

Fisher-Tropsch synthetic crude from natural gas

ENVIRONMENTAL

-

Caustic Scrubber

-

Biotrickling filter for converting H2S to Sulfuric Acid

-

Thermal Oxidizers

-

Regenerative Thermal Oxidizers (Using Dynamics)

REFINING

-

Atmospheric Distillation

-

Vacuum Distillation

-

Hydrotreating

-

Catcracker

DISTILLATION

-

Batch

-

Continuous

-

Continuous with Dynamics Package and ISA standards for the PID control loops

-

Divided Wall Column

-

Reactive Distillation

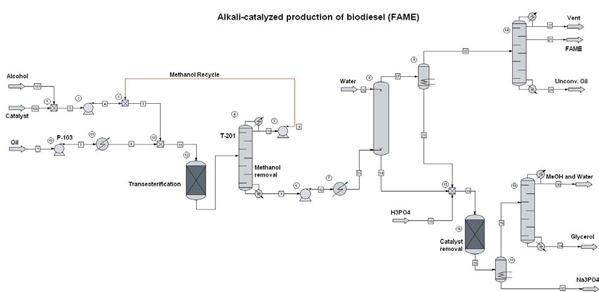

The following screen shows an alkali-catalyzed production of biodiesel

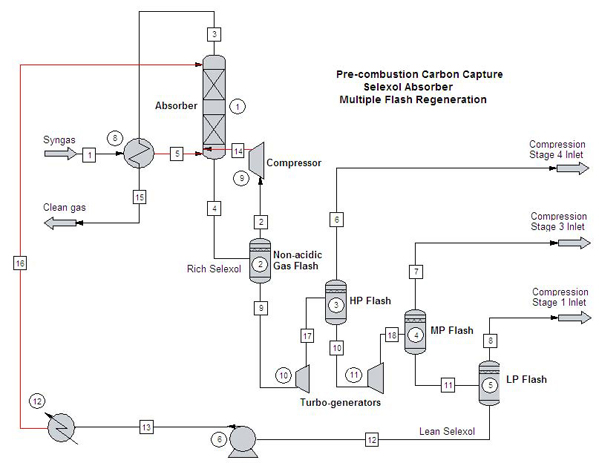

The next screen shows a carbon capture process using Selexol

We currently use a process simulation software package to perform the following functions:

-

Design of new processes

-

Troubleshooting of existing processes

-

What if studies

-

Sizing of heat exchangers, columns and absorbers, and control valves etc.

-

Providing clients with a model of their existing process for their own in house studies.

-

Optimization of processes for increased, production, quality and energy savings

We use only ChemCad 7.1.2, which includes its hydraulic network simulator safety net that is included within ChemCad. More information on ChemCad process simulation software can be found here.

Distillation Column Design Applications

For distillation column design applications please visit our distillation page.

More Information on ChemCad and Chemstations:

Personalized Technical Support

At Chemstations, we provide personalized, reliable support to every one of our users. Contacting the CHEMCAD support team doesn't involve wading through levels of representatives to get an answer. Customers are quickly connected with a friendly, knowledgeable team member who is highly proficient in chemical process simulation software.

Collaborative Approach

Chemstations is a privately owned company with a closely integrated group of developers, which lets us rapidly respond to—and even anticipate—customer needs by tapping into our industry knowledge to continually upgrade CHEMCAD's features. When changes take place in the industry, our team quickly assesses which new data and methods will be useful and viable additions to CHEMCAD. Additionally, if users require custom data or methods not currently in the CHEMCAD libraries, they can easily add the information themselves or with the guidance of the Chemstations support team.

Simulation Expertise

At Chemstations, we are industry leaders who couple our experience in simulation software with our clients' engineering expertise to form a partnership that results in optimized work flow and increased efficiency.

Flexible Platform

From complex process models to day-to-day challenges, CHEMCAD has the power and flexibility to meet user needs and exceed expectations. CHEMCAD has a tremendous range of capabilities, and because it is scalable and allows users to add features and customize as needed, it can boost productivity whether an engineer is using it to perform routine calculations or to tackle extensive projects.

Intuitive Graphical Interface

Throughout CHEMCAD's development, we have paid considerable attention to the way process engineers work. We understand the importance of designing software around the needs and goals of the users and adapting it to their workflow, instead of making them adapt to the software. To this end, CHEMCAD has been designed with an intuitive, graphical interface that enables users to do their jobs more efficiently. An open architecture allows for smooth interaction between our software and other commonly used programs. What's more, learning CHEMCAD requires less training than other simulation software, resulting in greater work efficiency and a higher return on investment.

Please call for further information

R.C. Costello & Assoc., Inc.

1611 S. Pacific Coast Highway, Suite 302

Redondo Beach, CA 90277

Tel: (310) 792-5870, Fax: (310) 792-5877

E-MAIL: rcca[at]rccostello.com